What is “Brush Tagnite?”

Brush Tagnite is a handheld selective anodize process that provides an environmentally safe and corrosion-resistant method to touch up small areas that have surface damage. The process involves the anodization of magnesium castings by using a brush or wand saturated with the Brush Tagnite electrolyte to deposit the Tagnite coating on the areas for repair with power being supplied by a portable rectifier. Brush Tagnite builds a thin, durable magnesium oxide layer that is approximately 0.10 (2.5 microns) thick. By using this hand-held process, the operator is able to selectively deposit an anodized coating to the areas of exposed magnesium without harming the rest of the part.

So Why do we use it? Typically after magnesium castings have been overhauled or repaired, a chemical conversion coatings such as DOW 19, Accelogold or DOW 7 is a applied to the repaired area(s) or the entire part to act as a base for paint. These conversion coatings contain hexavalent chromium (Cr6+) which is a known carcinogen, extremely thin and offer virtually no corrosion protection. Conventional anodize coatings provide better corrosion protection but the application process will not tolerate the presence of materials such as studs, inserts, bearing races or liners. Brush Tagnite was developed as a non-chromate, selective anodization process that is friendly towards those materials and provides better protection than chromate containing conversion coatings.

What are the advantages of the Brush Tagnite system?

- Better corrosion performance

- Enhanced galvanic corrosion protection

- Non-chromate, environmentally friendly electrolyte

- Suitable for all sand cast magnesium alloys including WE43 and EV31

- Compatible with organic sealants, primers and topcoats

- Excellent base for organic sealants, primers and topcoats

- Able to apply around ferrous materials

- Little, if any pretreatment needed

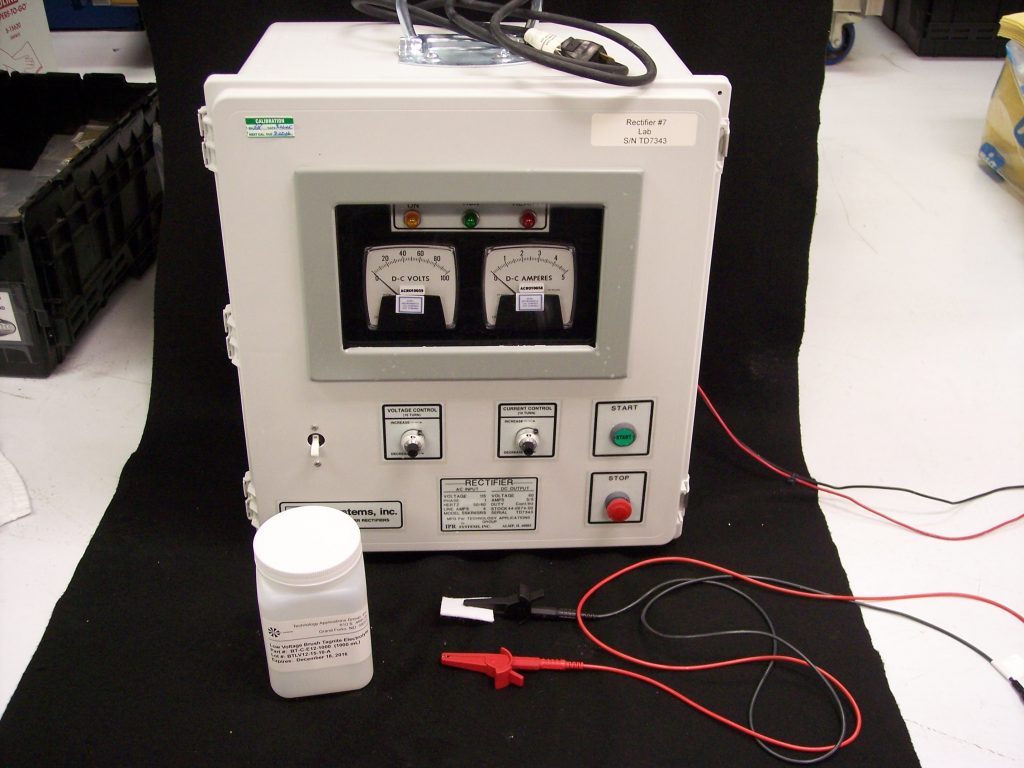

Brush Tagnite Equipment

Brush Tagnite Rectifier: A specially designed rectifier designed to be portable for rugged depot and field repair use as well as overhaul facilities. Operates using conventional 120 V DC and weighs 45 lbs. Delivers 50 V DC with 2 amp maximum output with typical working parameters of 20 – 25 V DC and < 0.8 amps.